Welcome to Cogrobo Lab

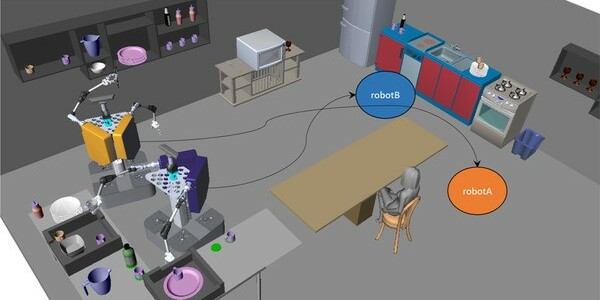

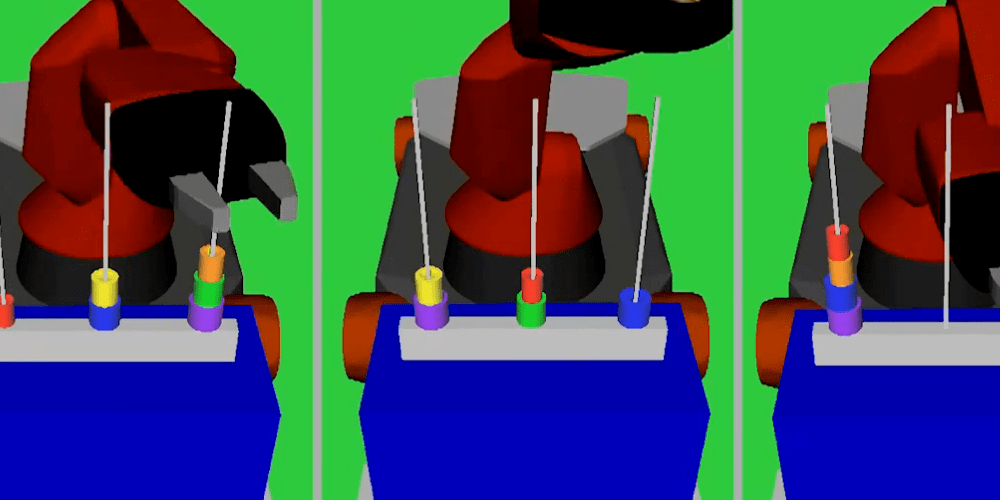

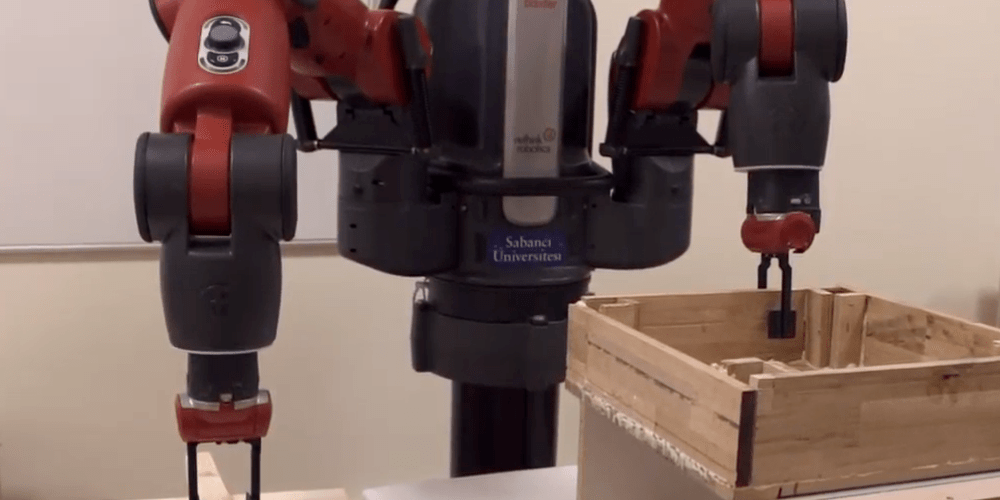

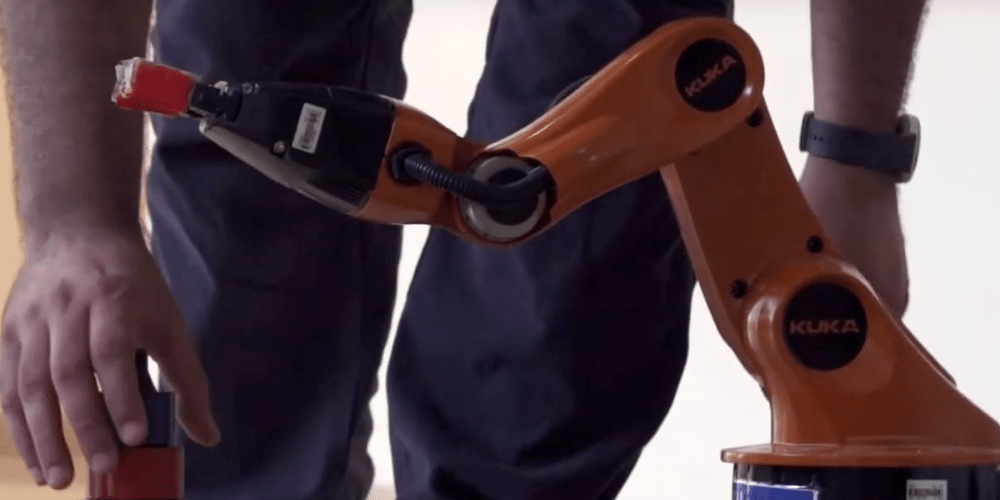

Cognitive Robotics is concerned with endowing robotic or software agents with higher level cognitive functions that involve reasoning, for example, about goals, perception, actions, the mental states of other agents, collaborative task execution. Our research has mainly been on bridging the gap between high-level reasoning and low-level control, involving both theoretical and hands-on components.

Due the interdisciplinary and synergistic nature of this research area, we study various topics, including kinematic and dynamic modeling of robots, architectures for robot control, world maps and localization, object recognition, manipulation and path planning, human-robot interaction, AI planning, sensing and monitoring, diagnosis, robotic learning, representation and reasoning formalisms and algorithms, and methods for coupling high-level reasoning with low-level control.

Cognitive Robotics Group has emerged from collaborations between Knowledge Representation and Reasoning Group and Human-Machine Interaction Laboratory.

We are looking for passionate new PhD students, Postdocs, and Master students to join the team (more info) !

News

26. January 2021Our new site is online. Please bear with us until it is properly populated.